Resource Recovery | Harsco Environmental

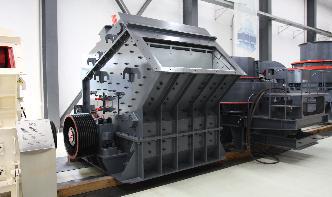

An invaluable Harsco Environmental service, resource recovery makes a significant environmental impact. Recovering valuable metal, we transform the nonmetallic byproduct into ecoproducts that create new and additional revenue streams for you. By way of various smelting processes, we then return the recovered metal in a form suitable for ...