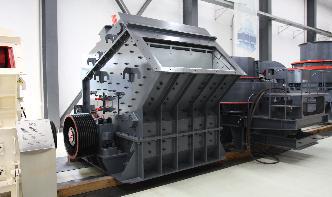

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

Laboratory Mills, Crushers and Sieve Shakers. RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.