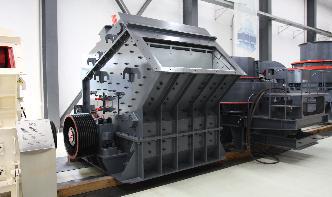

Crushing / Screening and Conveying

Primary crusher discharge size analysis. Throughput requirements and schedules. Mining Plans, Schedules, methods and equipment sizes. Effect on Circuit Selection. Determines selection of primary crushers and necessity for precrushing can influence this selection by determination of the product size at the required throughput rate.