explosions in coal mills

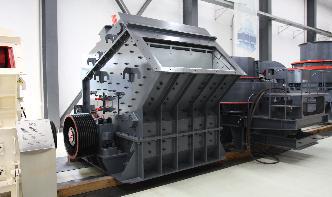

coal mill explosionsShanghai Jieke (Jack) Machinery Co., Ltd. coal mill explosions. Coal dust Wikipedia, the free encyclopedia Coal dust is a fine powdered form of coal, which is created by the crushing, grinding,... Read more. 1 COAL DUST EXPLOSION HAZARDS by CLETE R ... MSHA. pulverizedfuel systems, grinding mills, and other process or conveyance ... suspension that will .