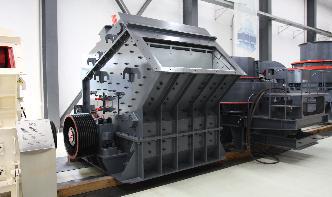

Crusher Construction Gyratory

Construction Function And Uses Of Gyratory Crusher 2. Construction gyratory crusher gyratory crusher outer shell of the crusher is constructed from heavy steel casting or welded steel plate, with at least one constructional joint, the bottom part taking the drive shaft for the head, the top, and lower shells providing the ...