Jaw Crusher|Differences Between Single And Double Toggles ...

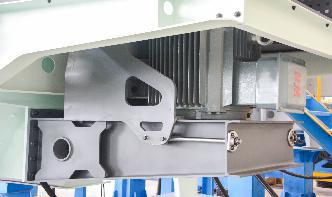

Jaw Crusher Double Toggle Jaw Crushers Single Toggle Jaw. Double toggle jaw crushers are preferred for crushing ususually hard abrasive rocks and other materials like ferroalloys and glass they differ substantially from other types of crushers there is no rotary motion in the crushing cycle and all crushing is done by compression of the feed material between two massive jaws plates