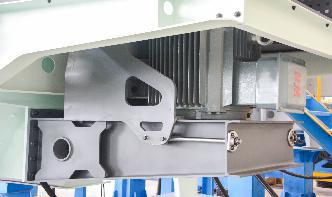

Roller Mill: Components, Designs, Uses, Advantages and ...

· Advantages of Roller Mills. 1. Produce more uniform, fewer fines, and oversized particles when it comes to product quality. 2. Generates less heat (0 – 3 0 C) unlike hammer mill that generates up to 10 0 C. 3. Less moisture loss. 4. Better work environment due to low machine noises level.