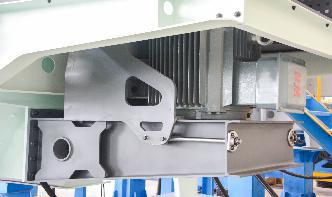

PHARMA BEAD MILLS | DYNO®MILL PHARMA | WAB Group

The WAB pharmaceutical mills are manufactured according to the highest quality standards for the pharmaceutical industry. Material selection, surface treatment and GMPcompliant design offer reliable production solutions for practical appliions. The metalfree grinding of active pharmaceutical ingredients is a standard option. We adapt the CIP and SIPcapable pharmaceutical mills to ...