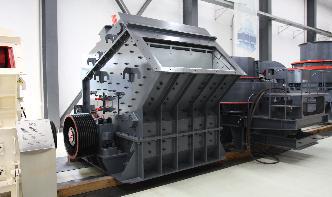

Avoid Unplanned Downtime: 5 Crusher Maintenance Best .

· Avoid Unplanned Downtime: 5 Crusher Maintenance Best Practices. Too many companies don't invest enough into their equipment maintenance, and ignoring maintenance issues doesn't make the problems go away. "According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs," says ...