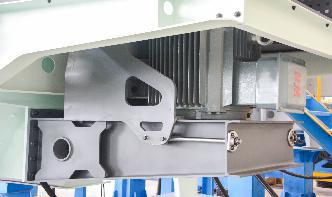

Process of Crushing Stone for Concrete Recycling

Process of Crushing Stone. The procedure of crushing the stone has three stages. The first stage is breaking down the stone to small sizes. The second stage is crushing down the sizable stones to suit a specific purpose. On the third stage, the stones are screened for finished products. Sand and gravel are the most common minerals used in ...