Hammermill Crushers | McLanahan

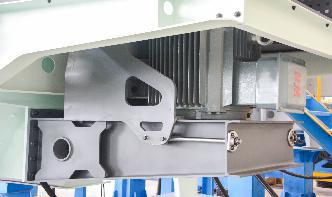

Screening after the mill allows for separation of the pulverized deleterious material, while the more cubical stone continues through the system. The Standard and NonClog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output.